We use cookies

While viewing our website pages, you agree that we process your personally identifiable information using metric programs. Read more

Understand, thanks

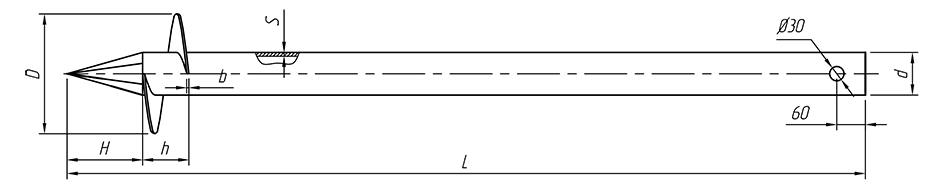

| Pile diameter, mm: | 73 |

| Pile length, m: | 2 / 2.5 / 3 / 3.5 / 4 / 4.5 / 5 / 5.5 / 6 |

| Wall thickness, mm: | 5,5 |

| Piles diameters, mm: | 250 |

| Pile weight, kg: | 20.7 / 25.3 / 29.9 / 34.5 / 39 / 43.6 / 48.2 / 52.8 / 57.3 |

| Tip: | welded |

| Tip length, mm: | 130 |

| Blade Pitch, mm: | 76 |

| Blade Thickness, mm: | 5 |

Helical blade piles are used in foundation construction in order to transfer a structure's load onto a stable substrate. The streamlined shaft surfaces of these piles are specifically engineered to minimize soil adhesion, thereby optimizing their performance.

А single helical blade pile is composed of a metallic tube affixed to the helix on a welded or cast tip.

A foundation constructed with helical blade piles eliminates the necessity for settling and is immediately capable of accommodating fresh loads, thereby significantly expediting construction progress.

When there is a need for rapid construction of relatively small structures, such as private houses, saunas, gazebos, and similar, it is advisable to use helical blade piles.

If possible, it is recommended that piles be manufactured at a facility that is specialized in helical pile production, rather than under impromptu circumstances. Also, it's important to remember some limitations when using this type of construction for building purposes.

First of all, helical products should not be used on rocky formations or in conditions where weak soil exists beneath a layer of solid earth.

Also important is to ensure adequate sharpening of the tips, as improper sharpening could hinder the correct installation, even that of a tree root. It is strictly prohibited to manually insert helical blade piles.

Using such a method indicates incompetence in this matter. A poorly executed installation of the pile foundation could pose a direct threat to the integrity of the entire structure it supports.

One final drawback pertains to the recommendation against executing installations during the winter months. This is a matter of economic impracticality, as creating a lead borehole would entail additional machinery costs, and screwing piles into frozen or debris-laden soil presents heightened complexity.

Specialists of the Screw Pile Plant will be happy to help you in selecting the optimal nomenclature and budget determination for your project.

Write to us and we will contact You within 15 minutes.

Learn more about the terms of cooperation, ask about the assortment, and request a customized quotation from our managers by phone or email.

More about us...While viewing our website pages, you agree that we process your personally identifiable information using metric programs. Read more

Understand, thanks